Postpress solutions from Koenig & Bauer

The ultimate in Postpress Flexibility

Be one step ahead in the industry.

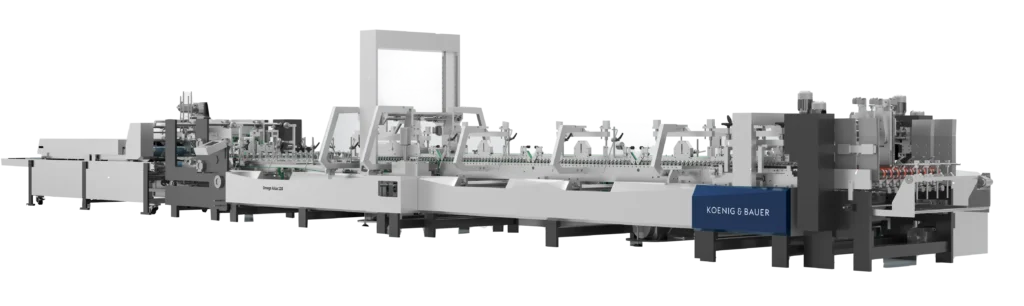

With Koenig & Bauer printing presses and innovative postpress technologies “Made in Europe”, you can take your entire folding box workflow to a whole new level. Our rotary die-cutter, flatbed die-cutters and folder gluers are your solutions for maximum productivity.

Cost-effective, reliable and packed with unique features. Just as you would expect from Koenig & Bauer – the leading provider of complete solutions for your folding carton production.

Postpress solutions from Koenig & Bauer

The ultimate in Postpress Flexibility

Be one step ahead in the industry.

With Koenig & Bauer printing presses and innovative postpress technologies “Made in Europe”, you can take your entire folding box workflow to a whole new level. Our rotary die-cutter, flatbed die-cutters and folder gluers are your solutions for maximum productivity.

Cost-effective, reliable and packed with unique features. Just as you would expect from Koenig & Bauer – the leading provider of complete solutions for your folding carton production.

Made in Europe

Our rotary die-cutter, flatbed die-cutters and folding box gluers are developed and manufactured in Europe – just like every Koenig & Bauer machine.

Cost-effective solutions

Whether purchase, maintenance or maintenance costs: our reliable solutions are investments that pay off for your business.

Maximum availability

With our intelligent postpress technologies you avoid unplanned downtimes and achieve optimal performance.

Highest productivity

Get the most out of your production! With postpress technologies from Koenig & Bauer you will even increase the efficiency of your highly automated production processes.

End-to-end connectivity

Our postpress solutions integrate 100% with Koenig & Bauer’s popular LogoTronic production workflow.

Individual configuration

Your business model – your custom solution. Each machine is configured and tailor made for you according to your requirements.

Postpress solutions from Koenig & Bauer

Because our satisfied customers speak for themselves.

We could tell you a lot more about the technology. But listen to our satisfied customers.

Made in Europe

Our rotary die-cutter, flatbed die-cutters and folding box gluers are developed and manufactured in Europe – just like every Koenig & Bauer machine.

Cost-effective solutions

Whether purchase, maintenance or maintenance costs: our reliable solutions are investments that pay off for your business.

Maximum availability

With our intelligent postpress technologies you avoid unplanned downtimes and achieve optimal performance.

Highest productivity

Get the most out of your production! With postpress technologies from Koenig & Bauer you will even increase the efficiency of your highly automated production processes.

End-to-end connectivity

Our postpress solutions integrate 100% with Koenig & Bauer’s popular LogoTronic production workflow.

Individual configuration

Your business model – your custom solution. Each machine is configured and tailor made for you according to your requirements.

Postpress solutions from Koenig & Bauer

Because our satisfied customers speak for themselves.

We could tell you a lot more about the technology. But listen to our satisfied customers.

Crossmark Graphics (US)

Accurate Box (US)

Unsere Faltschachtel-Klebemaschine Omega Allpro 130 von Koenig & Bauer ist eine von neun Faltschachtel-Klebemaschinen in unserer Weiterverarbeitung, aber auch eine wesentliche Komponente, auf die wir uns immer verlassen können! Durch den Einsatz von Beladerobotern konnten wir die Produktivität der Omega Allpro 130 von Koenig & Bauer von 13.500 Faltschachteln/h auf 15.000 Faltschachteln/h steigern.

Pedro Pacheco, Senior Director of Manufacturing; Samara Ronkowitz, Director of Sales and Marketing; und Lisa Hirsh, CEO und President

Vogtland Verpackungen GmbH (DE)

The John Roberts Company (US)

Koenig & Bauer’s Allpro folder gluer immediately opened up new opportunities for us and our sales team was able to upsell new packaging to win additional business.

We can clearly see that the Allpro folder gluer can process a wide range of customer orders from cardboard to corrugated.

Scott Zorn, Operations Manager, The John Roberts Company

KARTEX media packaging (CZ)

Our new Koenig & Bauer Rapida 105 and Optima 106 presses give us the opportunity to expand our offering both in terms of being able to run a wider range of substrates and expanded finishing applications. The Optima flatbed die-cutter impressed us with its ease of setup, robustness, compact design and excellent price/performance ratio.

Michal Havlík, Company Owner

Printing House Bardejov (SK)

The Bardejov printing company relies on printing and finishing technologies from Koenig & Bauer.

By investing in the new Rapida 76 printing machine and the Allpro 90 folder gluer for folding and gluing packaging, we are expanding our capacities and our product portfolio.

A company that is not innovative has no chance on the market. We can now process four- and six-corner folding boxes, and we have even quadrupled the capacity for one- and three-corner packaging.

Karol Dvorcák, Company Owner

Postpress – 100 % Koenig & Bauer

CutPRO X 106

Looks like a Rapida! And is the world champion in die-cutting – 100% Koenig & Bauer.

Flatbed Die-Cutters

Because top performance is pre-programmed with these technologies

The widest selection of tailor-made solutions for your die-cutting needs – 100% Koenig & Bauer

Folder Gluers

Because four high-performance product lines mean more variety for you

Our folder gluer line are all-rounders – whether cardboard or corrugated – you can produce the widest array of products – 100% Koenig & Bauer

Rotary Die-Cutter CutPRO X 106

A die-cutter as fast as your printing press

- Exceptional productivity through die-cutting speeds up to 16.000 sph

- Excellent production quality thanks to the highest register accuracy of 15 μm

- Significant reduction in waste thanks to extensive preset functions and Koenig & Bauer DriveTronic components

- Maximum flexibility through individual process units for almost limitless design diversity – from to embossing, creasing, to die-cutting to stripping and blanking

- Maximum ease of use thanks to a modern operating concept and intuitive user interface

- Packaging, Label, Commercial

- Fromultra-thin in-mold films up to 0,6 mm thick cardboard

- Convenient and quick job change from job to job – faster than traditional die-cutting

- Many well-known preset options from the Rapida series can be used

- Fastest job-to-job changeover speed via preset options known from our Rapida presses

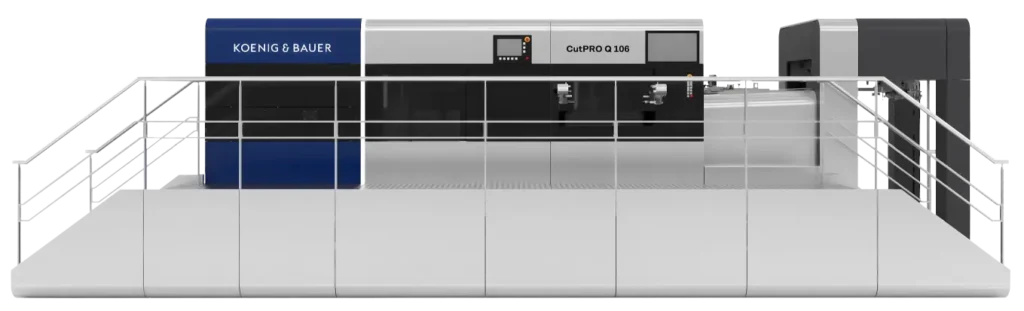

Flatbed Die-Cutter CutPRO Q 106 SB

The New Standard in Flatbed Die-Cutting

- Maximum output through die-cuttings speeds of up to 9,000 sph

- High substrate flexibility from 90 g/m2 paper to 1.5 mm cardboard and 3 mm corrugated cardboard

- Short set-up times and best performance in die-cutting production thanks to the latest automation

- Ergonomic and easy to use with advanced touch screens and an intuitive operating concept

- Unique Cut2Print register system: highest die-cutting quality thanks to unique registration system

- Compatible with other commercially available systems

- Unique selling point: most advanced feeder of any flatbed die-cutter on the market

- DriveTronic technology from the Rapida series for perfect sheet run

- Magic Carpet slip sheet system for continuous operation

Flatbed die-cutters Ipress 106 PRO S / Ipress 106 PRO SB

Newly Enhanced for your Performance

- Maximum output with die-cutting speeds of up to 9,000 sph (Ipress 106 S) and 8,500 sph (Ipress 106 SB)

- Total flexibility from 90 g/m2 paper to 1.5 mm cardboard and 3 mm corrugated cardboard

- Optimum sheet infeed and maximum production performance thanks to the Rapida’s Koenig & Bauer DriveTronic feeder

- Highest die-cutting quality thanks to perfect register enabled by the unique Cut2Print register system

- The unique Cut2Print register system guarantees perfect registers for the highest die-cutting quality. The register marks integrated in the color bar are scanned by two fixed front cameras and a variable side camera as the sheet enters the infeed, so that each sheet is precisely aligned. Cut2Print also captures markings on the side edge of the sheet and is therefore compatible with other systems available on the market.

- Absolute registration accuracy thanks to the new front register system

- Highly intuitive touchscreen operation for fine adjustment of the front marks

- Magic Carpet slip sheet system for continuous operation

Flatbed die-cutters OPTIMA 106 / OPTIMA 106 K

Our Allrounder for Your Folding Carton Production

- Maximum output with die-cutting performance up to 8.500 sh/h

- Maximum flexibility from 90 g/m2 paper to 1.5 mm cardboard and 3 mm corrugated cardboard

- Short set-up times for fast make readies

- Easy operation thanks to the intuitive operating concept

- Unique in its class – the VARIOPLAN® technology enables a cutting pressure of 300 tons.

- Highlight: the integrated blanking station of the Optima 106 K. The blanks are separated and placed in individual stacks on the pallet. Individual stacks of blanks can be separated using intermediate sheets, to obtain more stability – fully automatically and without interrupting ongoing production. This means the pallet can be safely transported to the next process step.

Flatbed die-cutter Ipress 145 PRO / Ipress 145 K PRO

From the leader in large format printing - Your large format die-cutter

- Highly efficient with die-cutting speeds of up to 7,000 sph

- Maximum material flexibility from 100 g/m2 paper to 1.5 mm cardboard and 4 mm corrugated cardboard

- Optimum sheet infeed and maximum production performance thanks to the Rapida’s Koenig & Bauer DriveTronic feeder

- Excellent register accuracy thanks to unique Cut2Print-Register

The unique Cut2Print register system guarantees perfect registers for the highest die-cutting quality. The register marks integrated in the color bar are scanned by two fixed front cameras and a variable side camera as the sheet enters the infeed, so that each sheet is precisely aligned. Cut2Print also captures markings on the side edge of the sheet and is therefore compatible with other systems available on the market.

The latest generation of the Ipress 145 blanking unit uses innovative tool technology where entire sheets can be processed quickly and easily.

The fully automatic shaftless DriveTronic feeder is perfectly tailored to your requirements. The innovative drive technology aligns the pile and separates the sheets precisely – regardless of the material to be die-cut.

Folder gluer OMEGA Allpro 55 – 145

The perfect all-rounder for maximum productivity and versatility

- Exceptional flexibility through format widths from 58 mm to 1,450 mm with a material range of 200 g/m2 board to 5 mm corrugated

- Maximum Output up to 400 m/min

- Shortest Setup times through fully automatic processes and memory function when changing jobs

- Process optimization through flexible connection for peripheral devices before and after the gluing process

- Reduction of waste and resources through precise, error-free folding and gluing – regardless of the type and shape of the folding box

- Included attachments for Z-folds, inner partitions and auto-bottom-boxes and CD packaging at maximum speeds of up to 400 m/min

- Innovative servo trailing edge folding system for economical production of 4 and 6 corner boxes

- Fully automatic make ready processes after simply entering the box parameters on the Allpro touchscreen

Maximum efficiency with our additional equipment:

- OMEGA stack feeder for the continuous material flow of cardboard and corrugated

- OMEGA Nick Breaker for efficient folding and gluing of blanks with a special layout

- OMEGA Turnpro rotates the boxes 90 degrees for an expanded production portfolio in one pass

- OMEGA Pack – the fully automatic, highly productive packaging system that can pack up to four rows and four layers – with just one machine operator

Folder Gluer Magnus 165 – 230

The powerful and robust corrugated cardboard specialist

- Maximum flexibility when processing folding boxes made of E, B, C and double flutes as well as heavy cardboard up to 900 g/m2 in format widths of 260 to 2,300 mm

- Performance and efficiency at maximum belt speeds of up to 300 m/min

- Shortest set-up times through fully automatic processes and memory function when changing orders

- Waste reduction through precise, flawless folding and gluing – regardless of the type and design of the product

- Process optimization through flexible connection to peripheral devices before and after the gluing process

- Expandable bracket for oversized blanks with vacuum transfer system

- Pre-breaker after final folding station pneumatic and independently operated on each side

- Extended folding system

- Folding belts with adjustable speed

- Pneumatic box straightener for the final folding of blanks on the upper belt (if the lower belt

is not used) - Feed transport systems with a high performance trombone unit

- Lower transport feeding system with feed control

- Easy operation with simple and comfortable controls

- Remote maintenance

- Remote control for operators

- Drive motors on both sides

- Color monitors for monitoring production

- Control panel at the end of the machine

- Memory function for repeat jobs (optional)

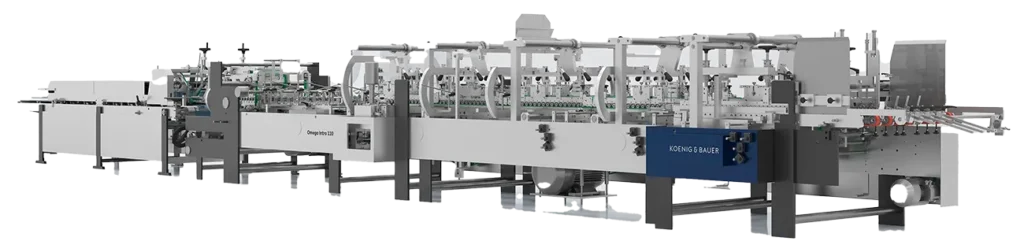

Folder Gluer Intro 110 – 165

The smart solution for your industrial folding carton production

- Unbeatable price-performance ratio

- Strong performance at maximum belt speeds of up to 300 m/min

- Precise and exact processing of folding cartons from 300 to 500 g/m2

- High flexibility when gluing and folding all standard and individual box designs with format widths from 96 to 1,650 mm

- Short setup times through motorized adjustment of all transport belts

- Process optimization through flexible connection to peripheral devices before and after the gluing process

- Tailor-made peripheral modules for your individual production requirements

- Based on the Allpro series

- This makes it equally versatile and suitable for a wide range of folding carton and corrugated substrates

- Three different sizes: 110, 145 and 165

- For folding and gluing all standard and many optional folding box types – including 4 and 6 corner boxes – with servo folding system, inner partitions, Z-folds, auto-bottom and conical crash lock as well as CD boxes

Folder gluer Alius 70 – 90 – 110

The answer for fastest job changes and high-speed production

- Leader in the High-performance folding carton production through maximum belt speeds of up to 600 m/min

- Very high Substrate flexibility – for almost all cardboard materials in the range from 200 to 550 g/m2

- Maximum Performance through numerous automation modules, such as: fully automatic calculation and setup of the belt positions based on the box design

- Maximum ease of use thanks to the intuitive operating concept via touchscreen

- Process optimization through flexible connection to peripheral devices before and after the gluing process

- Innovative solutions for individual requirements and production conditions

- High-speed production with belt speeds up to 600 m/min

- Fast job changes through innovative automation modules

- Available in three sizes – 70, 90 and 110 cm

- Optional servo trailing edge folding system for highly efficient production of 4- and 6-corner and automatic bottom packaging